3D Case | "One Road" Escort Helps Rubber Road Inspection

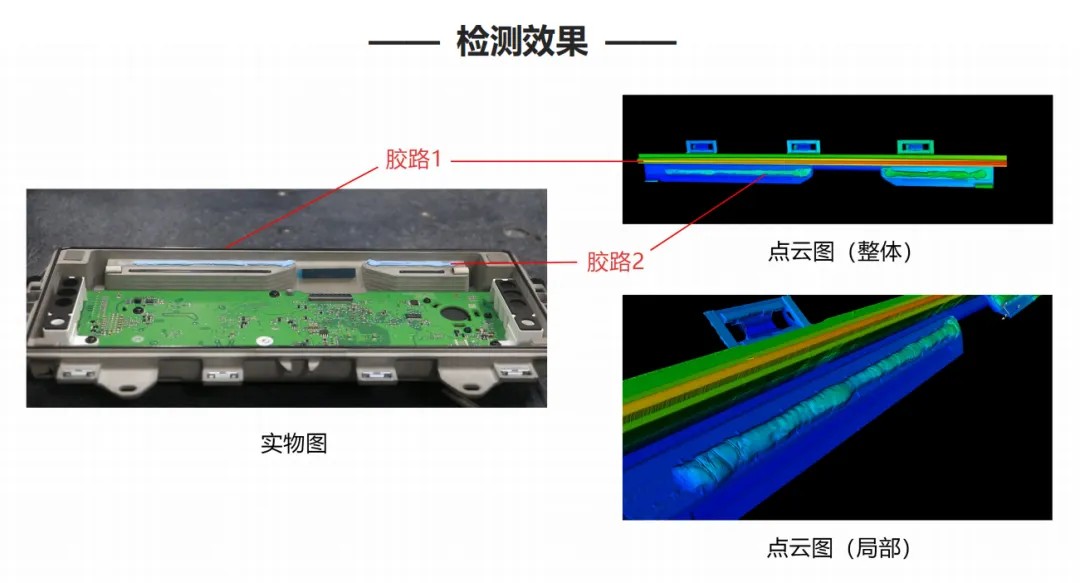

Rubber road defect detection

△ Detection requirement

Check if there is any glue accumulation or shortage in the glue path

△ Detection difficulty

1. It is necessary to simultaneously detect two rubber paths with different colors

2. The production line has fast speed and high requirements for camera frame rate

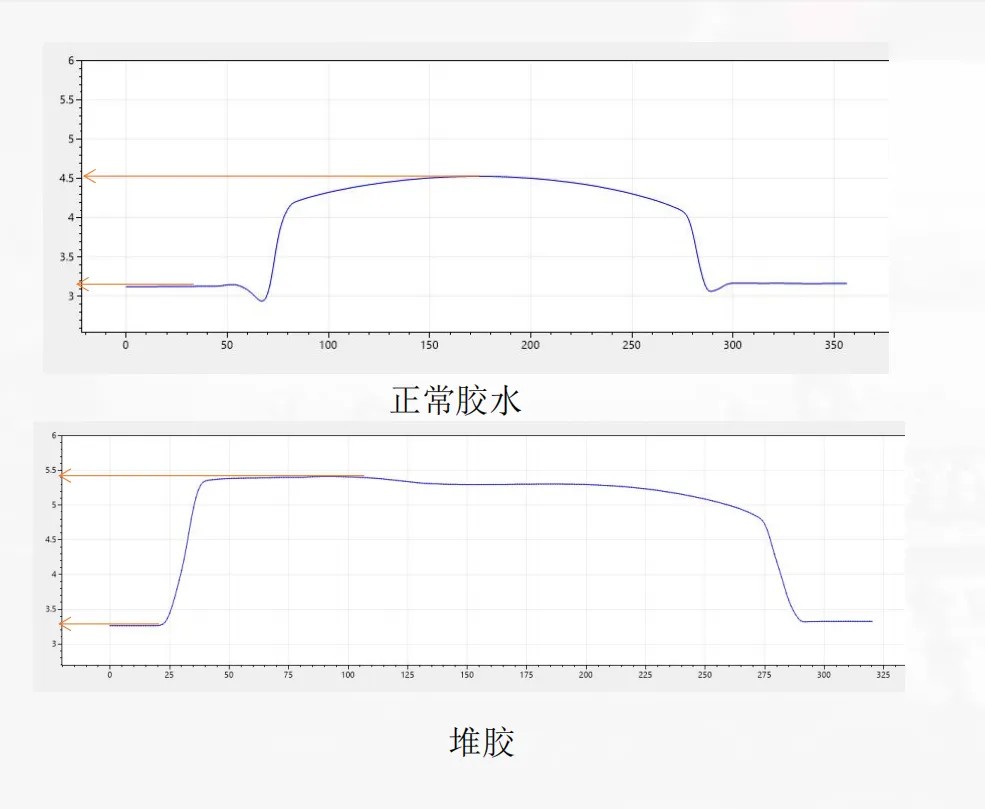

△ Measurement Instructions

Using the contour tool, calculate the height of the adhesive and use it to determine if there is a shortage or stacking of adhesive. The normal adhesive height is 1.378mm, and the stacking position height is 2.305mm

△ Plan Advantage

· Multi dimensional information acquisition, one axis scanning can obtain more adhesive road data

· High dynamic range CMOS compatible with different colors and multiple adhesive paths

· The sampling speed can reach up to 49KHz, quickly and accurately responding to

in high-speed production environments

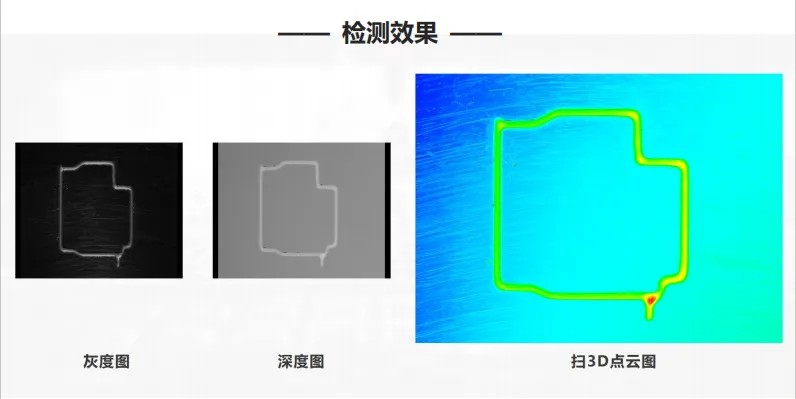

0 Thin transparent adhesive road detection

0△ Detection requirement

Detect the width and height difference of the adhesive

0△ Detection difficulty

1. The rubber road is thin and transparent, making it difficult to obtain real data

2. Irregular rubber road and noise prone imaging at corners

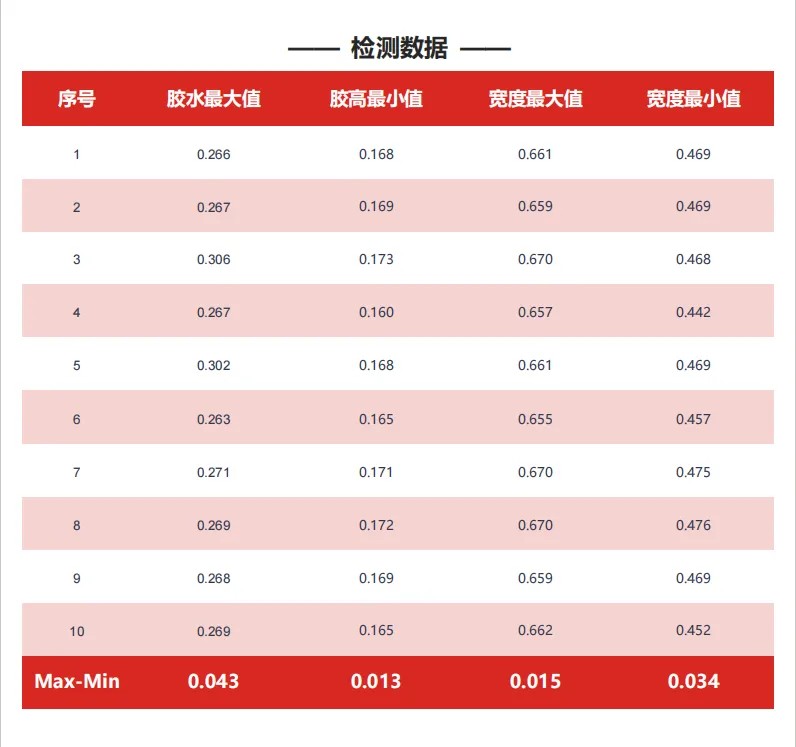

△ Measurement Instructions

· According to the SOP requirements, cover the entire rubber road

with a small rectangular ROI· The farthest distance from the small rectangular area to the substrate plane is the adhesive height

· The width of the adhesive in the small rectangular area is adhesive width

· Collect data for each small rectangle and calculate the maximum, minimum, and difference values

△ Plan Advantage

· Support single frame HDR, accurate recognition of high brightness/low contrast glue paths

· Can effectively suppress multiple reflection interference and provide clear imaging of adhesive road details