Generally, a single laser displacement sensor can measure the thickness of the measured object, but it is difficult to ensure whether there is an air gap between the measured object and the platform, and whether the measurement accuracy is affected.

In precision manufacturing fields such as electronic devices, semiconductors, energy storage, etc., the workpiece thickness is required to be extremely accurate.

In order to deal with the high standard thickness detection, PDH series laser displacement sensor is used for the photonics precision to measure the thickness by shooting, which provides a reference for the high precision thickness detection of the enterprise.

Two PDH series laser displacement sensors are symmetrically arranged up and down to obtain the thickness of the measuring block synchronously and continuously, and the dynamic measurement of the thickness of the measuring block is realized by combining the high-precision motion platform.

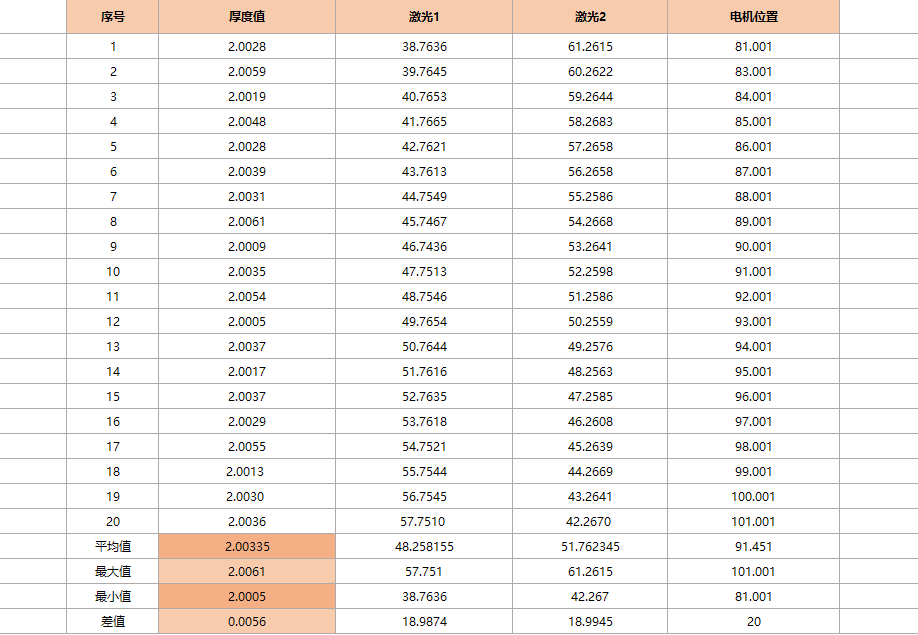

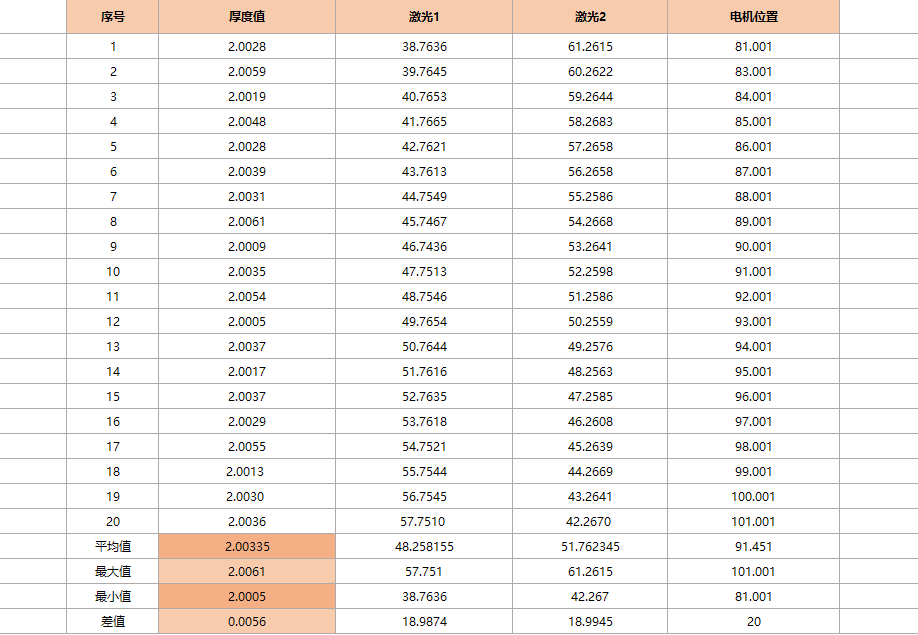

Test sample:2mm calibration block

testing instrument:Install one PDH series laser displacement sensor on each side, with a range of 50 ± 10mm, a repeatability of 0.035 µ m, a linear accuracy of ± 0.02% of F.S., and a sampling speed of up to 260KHz.

Motion Platform:Drive the measuring block to move up and down, covering 20 measurement points within the PDH range.

Dynamic testing of single point repeatability, measuring 20 times.

1.Effectively eliminate errors:The thickness measurement can effectively eliminate the errors caused by factors such as air gap and vibration in a single sensor.

2.High measurement accuracy:The PDH series has ultra-high repeatability and linear accuracy, combined with 260KHz high-frequency monitoring, which can more accurately and quickly capture small displacement changes of the measured object, greatly improving the accuracy and reliability of thickness values.

3.Flexible and efficient:The PDH series adopts a new optical design, which has excellent symmetry and synchronization of light spots, and can achieve precise up and down alignment. Combined with the dedicated upper computer software PDH Navigator, it is possible to conveniently configure and monitor data changes in real-time through menu options.

4.A wider range of measurement scenarios:The PDH series can achieve dynamic thickness detection for shooting thickness measurement, and can also stably detect workpieces with complex surfaces or irregular shapes, adapting to a wider range of measurement environments and objects.