Strength BUFF stacked PHOSKEY high-precision edge detection

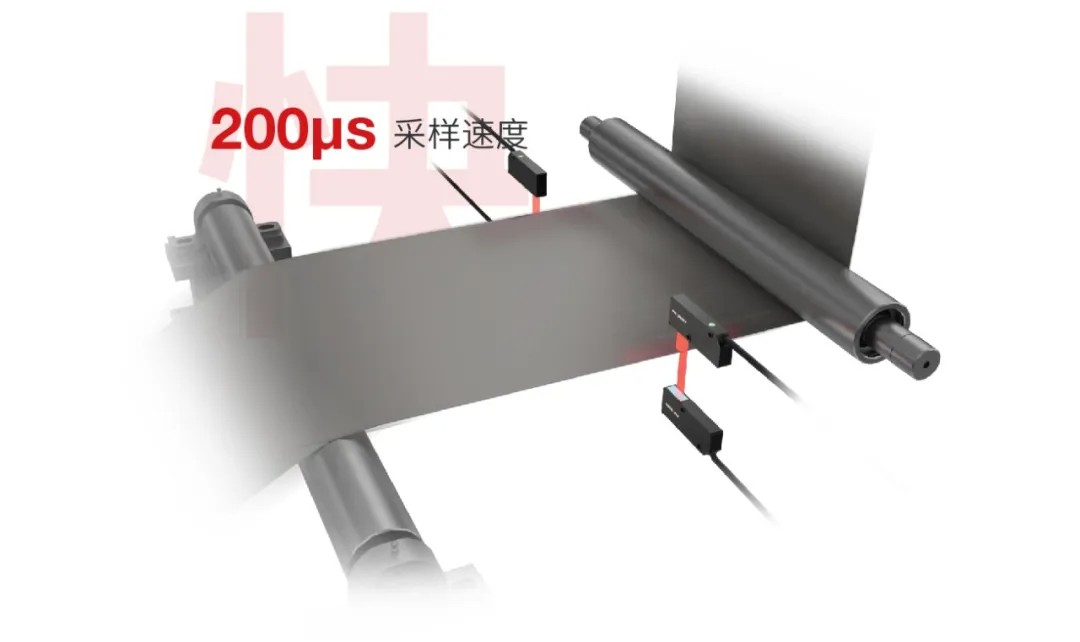

Fast 200μ Overspeed sampling, data collection at the moment of rotation

The PEL series of radial edge measurement sensors has industry-leading 200μ The sampling speed can quickly and accurately locate and measure the edges of workpieces even on high-speed production lines, meeting the requirements of precision machining and assembly. 0

Accurate Accurate edge computing, efficient measurement at micron level

The PEL series has ultra-high precision specifications and linear accuracy; 0.2% F.S., repeatability of 0.25μ m, Combined with the new self-developed edge detection algorithm, it can effectively deal with the challenge of high-precision deviation correction detection, suppress the impact of speckle and electronic noise, and achieve accurate edge computing. Easily handle scenarios such as automatic alignment and calibration, quality inspection, defect detection, and automated assembly.

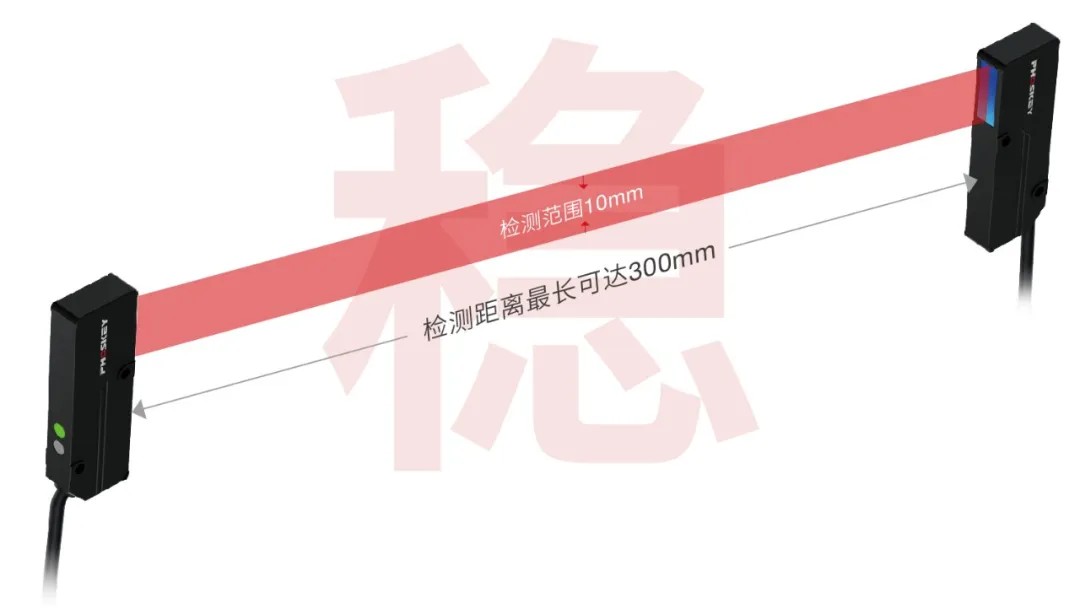

Stable Optical model algorithm, high-precision long-distance measurement

The PEL series supports a detection range of up to 300mm and utilizes nonlinear optical modeling algorithms to accurately calculate physical distances, effectively eliminating nonlinear errors and ensuring stable high-precision measurements across the entire range. Suitable for measuring workpieces of different sizes and distances.

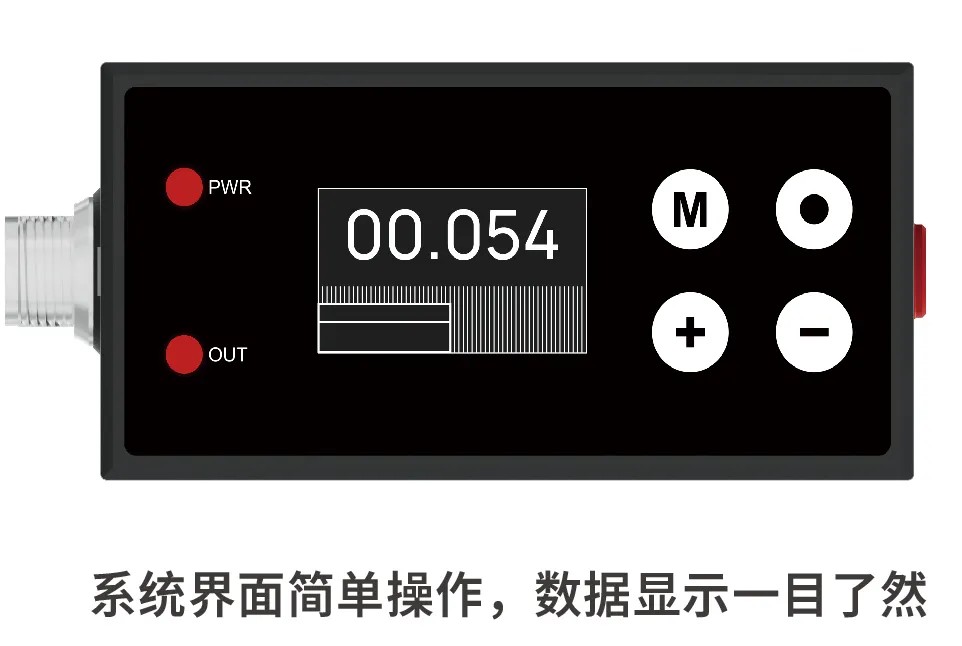

The PEL series is equipped with a MU-DM1- □ controller, which is compatible with analog voltage, analog current, and RS-485 data transmission modes, and integrates an OLED display screen for intuitive display of detection data. At the same time, it supports hard triggering function and can obtain real-time detection distance values. The PEL series also supports setting parameters for upper computer communication commands, enabling remote control and data management.

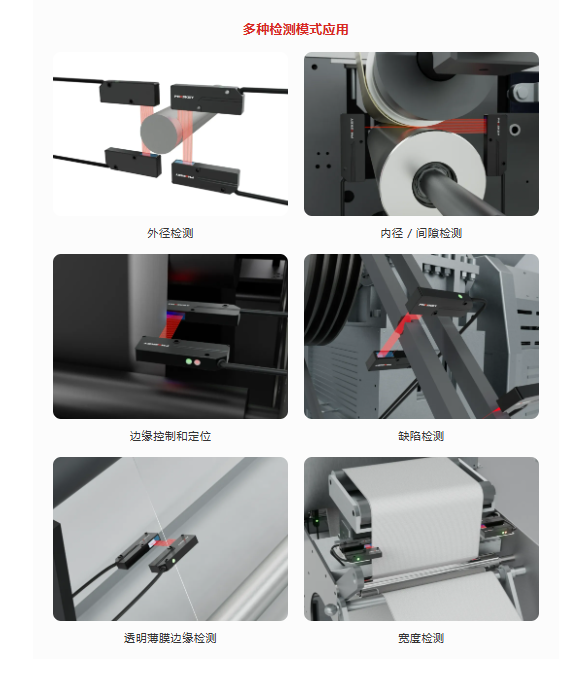

The reflective edge measurement sensor supports multiple detection modes, including edge detection, inner/outer diameter width measurement, spacing detection, transparent body detection, defect detection, etc., and can cope with various complex measurement scenarios. 0Multiple detection mode applications

0