Solution | New choice for cost reduction and efficiency improvement! Can label stacking be measured in this way?

On the automated packaging production line, hundreds of product labels can be attached every minute.

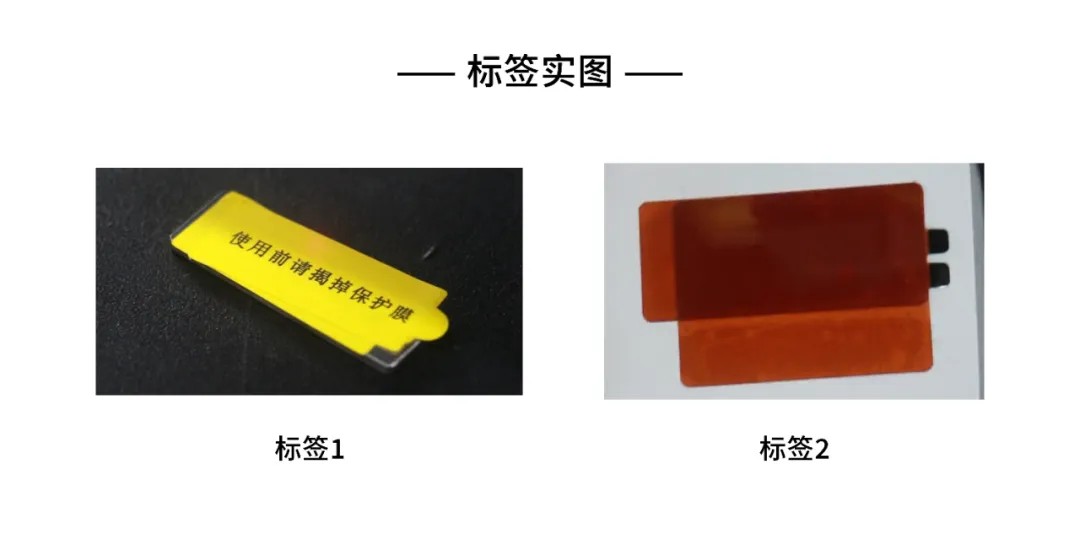

However, due to the thin and lightweight material of the stickers, traditional detection is difficult to identify. Frequent occurrence of label stacking problems in production leads to non-standard label adhesion, material waste, and affects production efficiency.To address this challenge, Photon Precision has designed this highly reliable stack detection solution for users, ensuring the efficient and stable operation of packaging production lines.

Label sticker stacking detection

Difficulty in detection

1. The thickness of the label is only about 0.5mm, which requires relatively high accuracy for the detection equipment.

2. Label 2 is made of semi transparent reflective material, which can easily cause unstable detection signals

3. The high-speed operation of the production line has put forward higher requirements for the response speed and stability of detection

PDM Series Laser Displacement Sensor

△ 0.1μ M repeatability accuracy, precise measurement of height differences with stacking and label wrinkles

△ built-in spot extraction algorithm, stable detection of transparent/semi transparent workpieces

△ with 4KHz ultra fast sampling speed, effectively responding to the visual operation interface of high-speed production lines

△, can accurately set the difference value to achieve precise control

Measurement instructions

PDM The series of laser displacement sensors are firmly installed on the sticker conveyor belt directly above through a bracket. When the sticker passes directly below the laser displacement sensor, setting the threshold for a single sticker allows for real-time and accurate monitoring based on the preset distance threshold.

Once a stacked sticker or wrinkled label passes through and its height exceeds the predetermined threshold range, the PDM series laser displacement sensor can immediately output a signal to provide feedback on the stacking situation.

1. Non contact measurement: does not require direct contact with the label, avoiding label wear and contamination issues.

2. Quick response: The transmission speed of the laser beam is extremely fast, enabling real-time detection on high-speed production lines.

3. Strong adaptability: It can adapt to the detection needs of stickers of different materials, sizes, and shapes.

4. Low cost: Suitable for budget requirements and requiring low-cost solutions.