The China International Fair for Industry and Technology is here to witness the exciting moments at the exhibition!

0At this exhibition, PHOSKEY not only set up a centralized display area to showcase its core products in all aspects, but also equipped a professional technical team to customize personalized solutions for the attending guests. On the first day of the exhibition, our strength made a name for ourselves and our customers were like clouds. 0The Industrial Fair will last for five days (9.24-9.28), and the excitement continues! PHOSKEY cordially invites friends from all walks of life to visit booth A059 in Hall 5.1 for in-depth exchanges and to join in the grand event!

△Professional optical system, ultra-high precision measurement, with up to 4096 contour points

△ Extreme ultra-high sampling speed 49000 contours/second

△ Covering 7 models, suitable for measuring and testing various complex industrial parts

Circular Splicing Detection

Equipped with a large aperture detection lens, an ultra wide X-axis field of view, and ultra-high resolution, it can efficiently and accurately collect data through multi camera ring stitching. Under network linkage, comprehensive diameter measurement and surface defect detection of objects can be achieved.

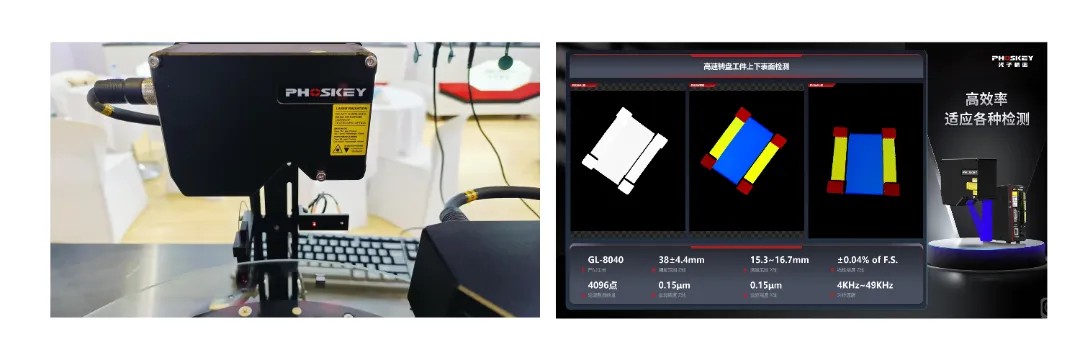

High speed turntable detection

The sampling speed for full frame can reach 4KHz, with a maximum of 49KHz. And it has 4K ultra-high resolution, and small-sized workpieces can also be imaged at high speed and high quality, ensuring that the detection accuracy and speed meet the production line requirements

Flatness/Height Detection

Supporting native single frame HDR and multi frame HDR synthesis, it can simultaneously measure the surface of dark (low reflectivity) and reflective (high reflectivity) phone frames, achieving high-quality imaging of composite material workpieces.

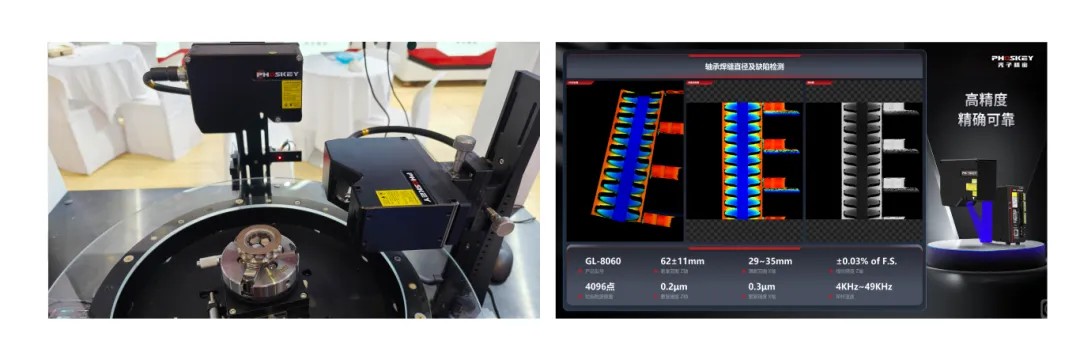

Bearing weld seam inspection

Built in advanced imaging algorithms can effectively suppress interference such as reflection, occlusion, multiple reflections, diffuse reflections, etc., ensuring the accuracy of detection results. Stable detection of workpieces with small features such as grooves, protrusions, patterns, and metal coatings that can easily cause interference from reflected light.

OCR Character recognition

The measurement range of X-axis and Z-axis is large, and larger workpieces can be scanned in one go; Supports single frame HDR, effectively dealing with complex characters, background interference, and other situations; Equipped with ultra-high resolution and ultra fast scanning speed, it can meet the efficient and high-precision detection needs of the production line.

There are more 3D cases waiting for you to open on site

NO.2 0Laser displacement sensor PDM/PDL series

△Exclusive ultra-fine dynamic dimming technology, with dimming particle size far exceeding imported similar products by more than 10 times0△ Multi functional RS-485 communication mode optional

△ Meet various detection tasks such as thickness, height, roundness, step difference, displacement, warping, vibration, flatness, etc.

NO.3 0Reflective edge measurement sensor PEL series

△ Capable of 200μ Sampling speed

△ Linear accuracy± 0.2% F.S., repeatability of 0.25μ m

△ Supports detection range up to 300mm

NO.4 0Color Sensor PW Series

△ Using a white light source, it can receive visible light in all wavelength ranges

△ With ultra-high color detection accuracy and stability

△ Single/dual spot options available

NO.5 0Photoelectric sensor

△ Equipped with BGS function, stable detection of

△ IP67 protection level, sturdy and durable

△ Adopting a unique chip and external anti-interference algorithm

NO.6 0Fiber optic sensor

△ High speed response speed, significantly improving production efficiency

Unique fiber optic transmission method ensures signal stability and anti-interference ability0△ High protection shell, more sturdy and durable

NO.7 0Proximity sensor

△ Stable performance, sensitive sensing

△ Compact size, easy to install

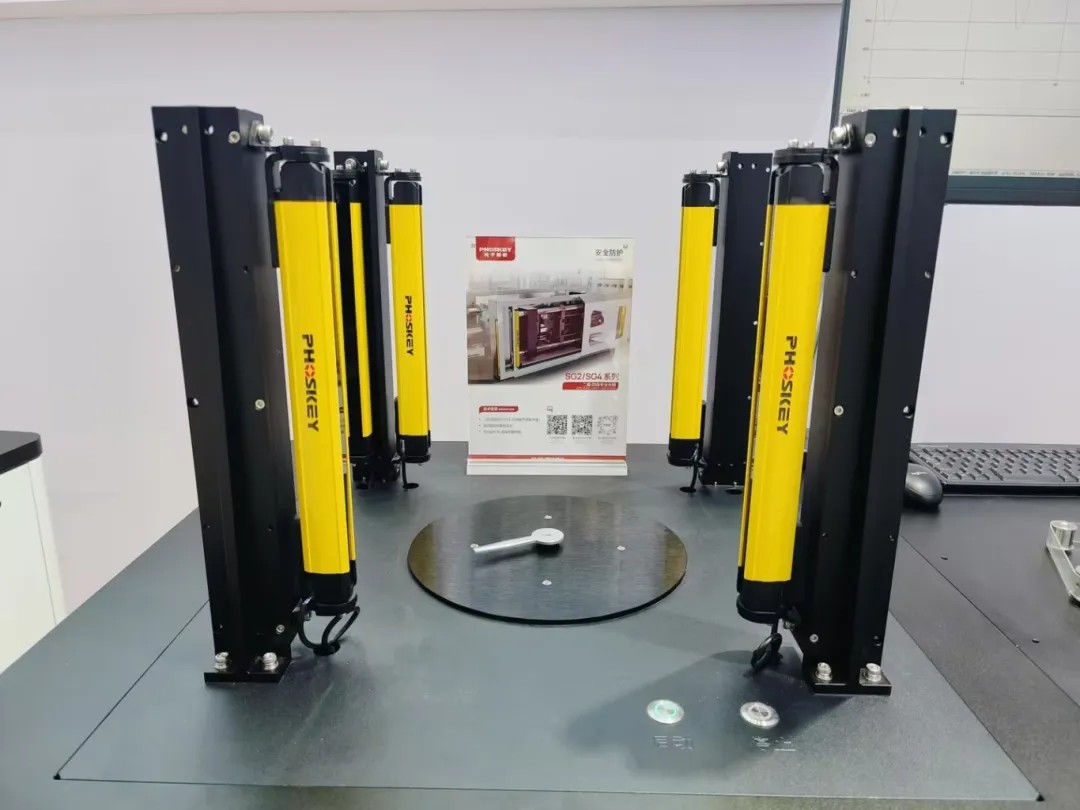

NO.8 0Safety grating

△ Anti electromagnetic interference, strong anti light ability

△ Dual circuit self checking output design, no blind spots in the field of view